The painting production line of the complete machine is designed by the former First Design and Research Institute of machinery Industry, which adopts the advanced and mature industrial art in China at that time, and improves the mechanization and automation level of the painting production line, so as to improve the working environment and reduce the labor intensity of workers. At the same time, it has earnestly implemented the relevant state laws and regulations, norms and standards, and worked hard to do a good job in environmental protection and occupational safety and health.

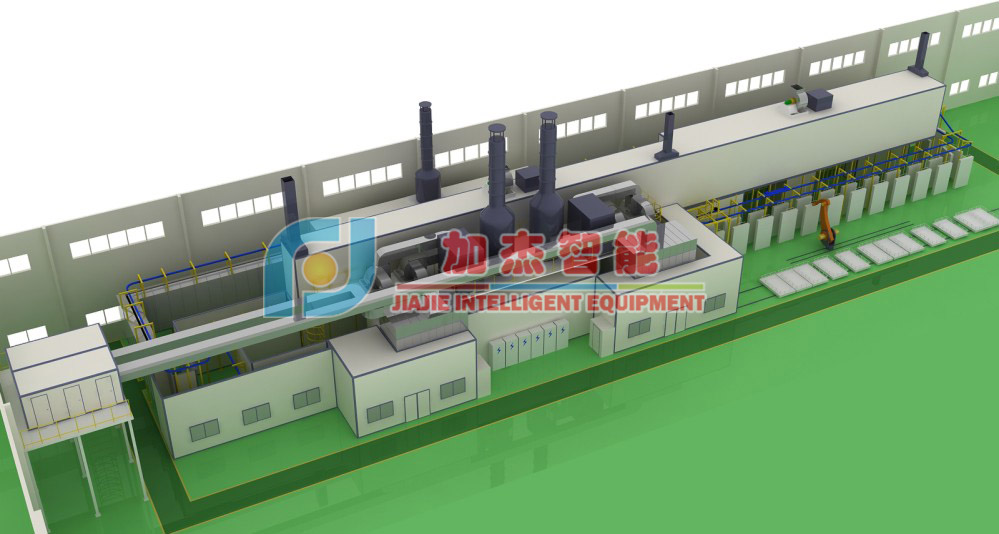

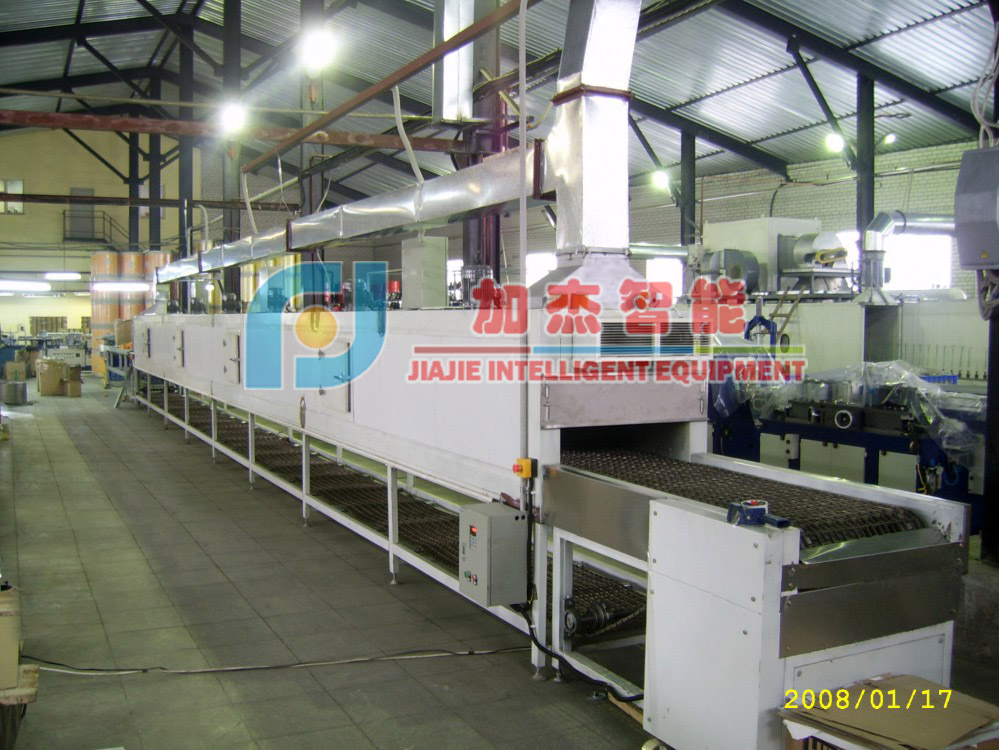

The whole production line by line, drying, screening, drying, paint on the surface and, offline 7 station such as composition, except on and off the five stations by an organic water drying room, shielding room, water spray paint room, flow flat room and dry room of a closed production line, and workshop is separated, ensures the whole paint areas relatively clean. In addition, a complete machine cleaning section is built at one end of the workshop for secondary cleaning of the complete machine. The whole machine adopts double board ground chain transportation to improve the mechanization level.

Process flow: water gun oil removal cleaning -- on line -- hot air drying -- shielding -- surface paint spraying -- leveling -- drying -- removing shielding -- off line.

The operation time of each station is 45min, and the cycle time of the pipeline can be adjusted appropriately according to the actual use.

The paint varieties are komatsu yellow acrylic polyurethane enamel and the spray gun is electrostatic mixed air spray gun.

The coating production line can produce 2000 loaders per year when only units are arranged for production. The total number of designers in the coating workshop is 24, including 16 production workers. The average annual output of each production worker is 142 loaders.

Second, the question raises

After 2003, due to the country to increase the investment in infrastructure, the loader industry into the good situation of flourishing production and marketing, several major loader production enterprises have reached their maximum output record. At the same time, each manufacturer has improved the appearance quality. The paint is mainly used to color the loader. The loader's appearance color is divided into two parts, which changes the loader's single color for a long time.

With the increase of loader output and the extensive use of exterior paint color registration, several problems occurred in the application process of complete machine coating line:

(1) the surface spray paint tinted homework makes loader shorter time () down on a painting area, and screen instead of to shorten the time, and extension of trend, make the whole assembly line beat changed, when in low yield, but increased the waiting time for some station, yield increase and then need to be partially blocked work offline.

(2) Due to the shortened beat of the entire production line, there is a heating process in the water mark drying room, so that the temperature just rises to the specified temperature and sometimes even does not rise to the specified temperature, it needs to be transferred to the next station, which cannot play a role at all. However, the water mark drying room is a pass-through type, and the temperature immediately drops to the ambient temperature after the door is opened.

(3) The drying room also has the same problem as the water mark drying room, which cannot give full play to the drying role.

(4) The door of each chamber adopts pneumatic door, the time of switch is long, fully open or completely close is about 3-5min, in the whole beat is long (45min), do not feel, after the beat is shortened it seems a little too long.

(5) the utilization rate of the waste gas treatment device is too low, because the exhaust gas in the paint room is fully mixed with water, and the air volume is large, so the organic solvent content discharged into the atmosphere can meet the emission standards. The drying chamber USES the hot air circulation, a small part of the exhaust gas emissions, this small part of the exhaust gas may exceed the standard, so most of the production lines have added activated carbon adsorption device.

3. Suggestions for improvement

It is impossible to solve the above problems by using the current intermittent pass-through production line. To completely solve the above problem, only fundamentally change the production line type, or like a car factory adopted by type production line, continuous operation, every room body is longer, the whole production line without door, drying room a preliminary drying and strong cold area, and use the wind curtain interception heat, or use the Chambers and decorate, a spray room with 2-3 drying room, loader into the drying chamber immediately after spray paint, flat, drying in the process of heating up, some large-scale passenger car manufacturer both in this way.

Iv. Practical operation

With the increasing production of loaders, the measures taken by our company are as follows:

1) After cleaning and removing oil, the loader should take the way of natural cooling and drying, pay attention to maintain balanced production, if the weather is bad, use the night time to dry.

(2) When the production line is in operation, the water-mark drying room does not work, and most of the shielding work is carried out offline.

(3) All the doors of the room are closed when painting, in order to save time. In this way, it is easy to cause the paint mist to fly to the shielding room and leveling room next to the paint room.

(4) A new 720m2 hangar will be built for parking the loader sprayed with paint, and the painting and decoration work will be carried out here; When the temperature is low, use the evening time to dry.

(5) Make some baffles of shield glass with tin sheet to save the time of shield glass.

Through the above measures, the company has ensured the painting workshop in the case of no night shift, Nissan 15-20 loaders. Of course, the above measures are a little harmful to the production line. In order to improve the problem of drying in winter, the company plans to build a new drying room for drying the paint of the whole machine, and prepare to move the water-mark drying room below the line to play its role.

客戶服務熱線

客戶服務熱線